What is TFM?

Total Focusing Method (TFM) is an examination technique, that has been added into codes and standards and is becoming increasing used across all engineering sectors including aerospace, nuclear and oil & gas. The method involves the combination of classic Full Matrix Capture (FMC) data acquisition and TFM data reconstruction. It has the potential capabilities of improved resolution and depth of field over a larger region with a reduction in scattering of sound waves from material noise, enhancing efficiency and performance (ASME section V article 4, 2019 edition).

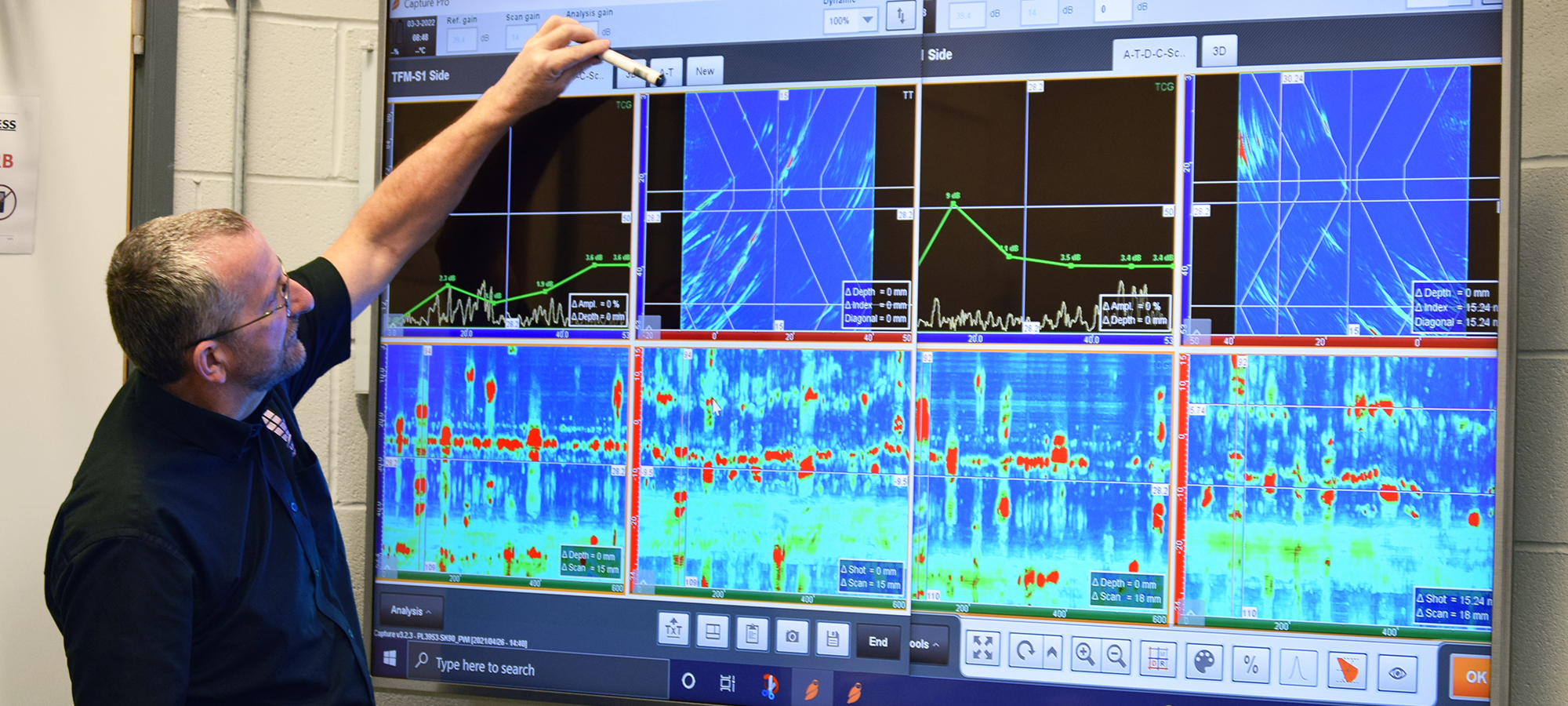

Our TFM course is designed to educate advanced inspectors in the methodologies and techniques to accurately identify and interpret flaws in challenging inspections, focusing on the use of ultrasonic imaging algorithms that improves the profiling of the indication. Candidates will learn about the TFM processing software to reconstruct several paths/modes, evaluating and examining flaw characterisation, flaw dimensioning, display settings, plane wave imaging (PWI), weld and corrosion examinations and amplitude fidelity.

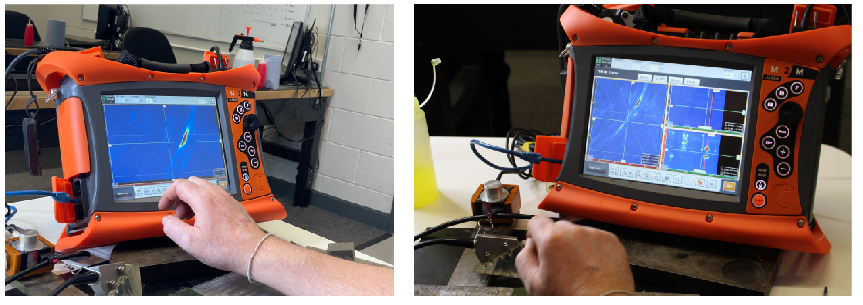

The course syllabus has been written in accordance with ASME Section V and 2020 SNT- TC-1A. It will cover the theoretical understanding of TFM in addition to hands-on testing using the latest equipment.

The Level 2 advanced course will address the following issues:

• Overview of PAUT and FMC data collection

• Beam forming and resolution

• Amplitude fidelity, interface/dead zones and calibration

• Sensitivity correction

• Corrosion mapping

• FMC characteristics (direct modes and bi-modal techniques)

• Plane Wave Imaging (PWI)

• Understanding the various modes used in TFM and benefits of enhanced detection, characterisation and sizing

• Inspection of vertical angled joint faces

• Evaluation and examination including display settings, flaw characterisation, flaw dimensioning and software tools

• Weld and corrosion examinations including single v and double v welds

• Practical use of TFM phased array applications for austenitic stainless-steel and ferritic steel weld inspection

• Hands on practical testing on a wide range of samples using the latest technology equipment

Pre-requisite

To be eligible for this course candidates must hold UT Level 2 Welds PCN or SNT certification. Ideally candidates will have an understanding of PAUT.

“At Lavender International we pride ourselves on delivering high quality training that equips technicians with the skills in making more informed decisions on equipment selection and optimising instrument parameters resulting in a more well-rounded, highly skilled, certified advanced NDT inspector,” Tim Armitt, Managing Director and President, commented.