What is Computed Radiography (CRT)?

Computed Radiography uses photo-stimulated luminescence to store x-ray exposures. First, a phosphor imaging plate is placed behind the component and is exposed to penetrating radiation. This plate is then scanned (figure 1) to create a digital image of the exposure by detecting the luminescence from the plate’s photostimulable luminescent phosphor.

Computed Radiography uses photo-stimulated luminescence to store x-ray exposures. First, a phosphor imaging plate is placed behind the component and is exposed to penetrating radiation. This plate is then scanned (figure 1) to create a digital image of the exposure by detecting the luminescence from the plate’s photostimulable luminescent phosphor.

CRT effectively creates an image much like traditional X-ray, but using different equipment, which then is scanned into a computer as a digital archive.

How Does it work?

Computed radiography uses a barium fluoro bromide which uses europium as an activator. Barium absorbs the x-ray energy to create what’s known as a latent image.

Photostimulable luminescence (or the emission of light) is used to transfer the latent image to the computer. Red light excites the latent image that’s stored, which is then transferred through the imaging plate to come out as a blue light. The blue light goes onto a pentaprism or a parabolic mirror, and the energy of the light is redirected onto a photomultiplier tube, which receives the light. There is a scintillating material in front of this (known as a photocathode), which takes the blue light and converts it immediately to electrons. The electrons rotate down the photomultiplier tube by gating systems called dynodes. These dynodes collect all the electrons and send them to an Analogue to Digital Reader (ADR), which starts to create an image on your digital screen.

Benefits of CRT:

- CRT uses a traditional X-ray room and as such, companies with an existing conventional X-ray set-up do not need to invest in different X-ray rooms.

- The use of cassettes instead of films means that traditional dark rooms and film developing equipment is no longer required. Instead, investment is needed in the CR equipment which includes: a scanner, and main frame pc to run the software. This is relatively expensive to set up and, once set up, is favourable for production/repeat work.

- Traditional film can be slow to develop and archiving film is problematic for long term storage, computed radiography creates a digital archive which is easy to distribute and easy to maintain. Problems in conventional radiography such as film degradation is no longer an issue.

- The imaging plate is re-useable as opposed to conventional film, which either must be stored or disposed of.

- There is a significant reduction in exposure times in most cases, however energy needs to be the same as conventional RT.

- The end result is high resolution images that can be digitally shared amongst customers, colleagues and companies.

- There is also a large reduction in re-shots as opposed to traditional radiography, as the technician receives immediate feedback from the shot.

Therefore, this one-time purchase requires less maintenance than conventional radiography which requires film development equipment.

What is Digital Radiography (DR)?

Digital Radiography uses a sensor that provides an immediate digital image of the radiograph and effectively acts as a digital feed of a scan in real time.

How Does it work?

Digital Radiography is a system of electronic components, which, by either directly detecting radiation or converting analogue radiation detection information, creates an image of the spatial radiation intensity map comprised of an array of discrete digital intensity values (pixels).

DR can be divided into two categories: indirect capture and direct capture.

Indirect capture digital radiography devices absorb X-rays and convert them into light. The light is then detected by an area-CCD or thin film transistor (TFT) array and then converted into an electrical signal that is sent to the computer for processing and viewing.

Direct capture devices convert the incident X-ray energy directly into an electrical signal, typically using a photoconductor as the X-ray absorber, and send the electrical signal to the computer for processing and viewing.

DR can be expensive to invest in and requires a DR panel with a live Ma X-ray set to amend the intensity values to 30%. The DR panel is a consumable and will be affected by the X-ray intensity. However, gamma is kinder to the panel and therefore, it won’t degrade as much.

Benefits of DR:

- Due to it’s high-speed workflow, DR proves to be a highly efficient process of radiographic testing. Therefore, demand has increased in recent years and companies are turning towards DR for NDT inspections.

- Whereas in conventional X-ray and CR a traditional X-ray bay is installed, for DR, a detector is installed in the bay. The image will appear in 3 to 5 seconds, and the technologist knows right away if the image needs to be repeated.

However, it must be noted that as Digital Radiography is a relatively new development in the Non-Destructive Testing industry, the method has no centrally recognised issued certification other than SNT or NAS410 EN4179. There is not yet a recognised ISO 9712 certification for Digital Radiography courses in the UK.

Applications of CRT and DR:

- A major use of CRT and DR in asset integrity management is looking for Corrosion Under Insulation (CUI), which is a major problem. Both methods can shoot through the pipe lagging and reveal loss of wall subsurface. This is a great alternative to UT inspection through stripping off the lagging, which can be costly.

- Both CRT and DR are largely used in inspecting castings due to the wide dynamic range to assess differing thicknesses.

- CRT of welds is common practice due to improved resolution of the image plates. The duplex is a key indicator to prove resolution but shall be used alongside contrast image quality indicators in accordance with the ISO 17636-2.

CRT courses at Lavender International…

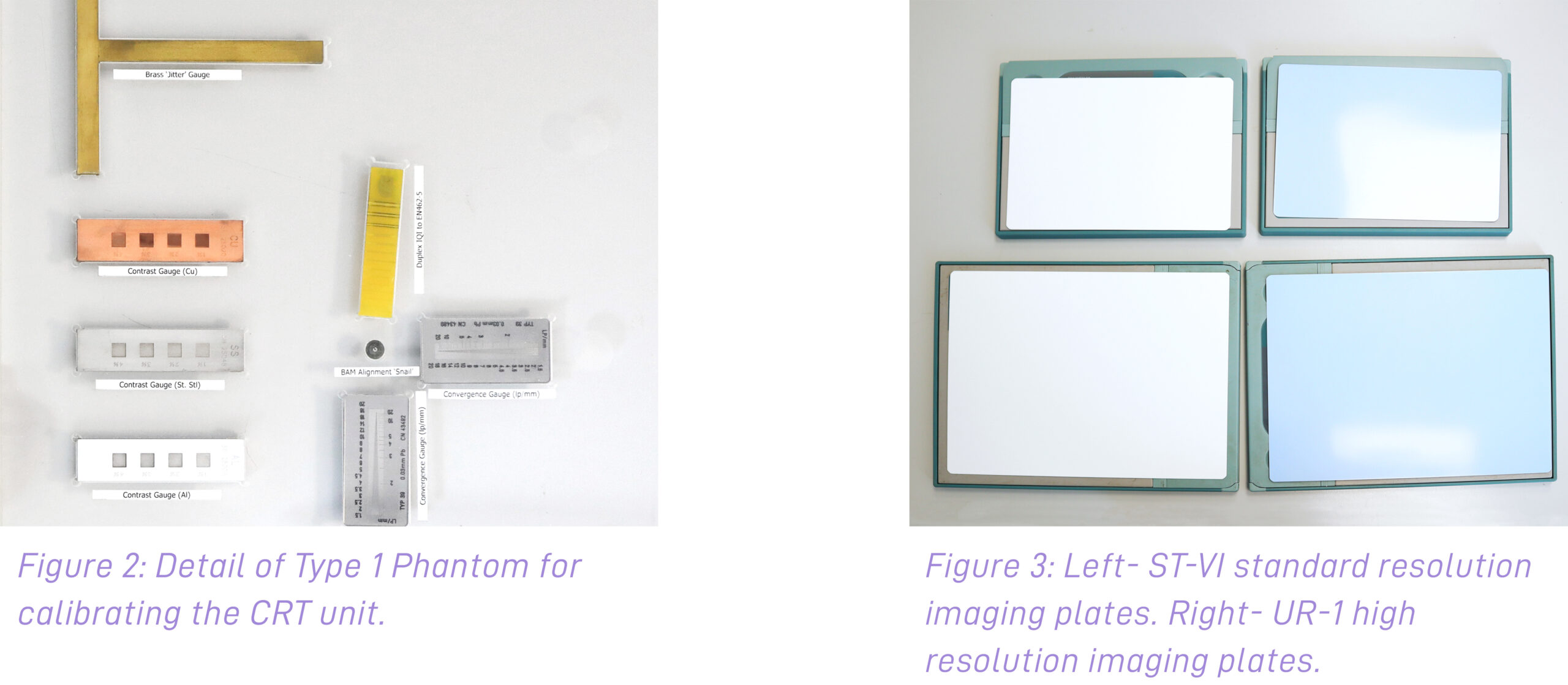

Lavender International have recently invested in new equipment for the Computed Radiography (CRT) courses. This Level 2 PCN certified course, taught by our expert tutor Andy Greenwood at the training school in Penistone, Yorkshire, gives students 40 hours of Computed Radiography training, with examinations including a specific paper, practical and interpretation exam. This course is also offered for SNT-TC-1A, NAS410 and EN4179 Welds or Castings. The course covers basic radiology physics, an overview of Computed Radiography, system components, basic CR techniques, Digital image processing and viewing, and calibration of equipment (Phantom).

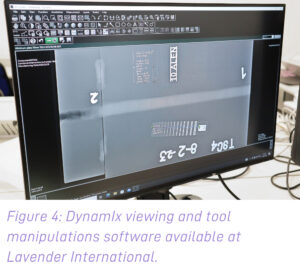

The students use the DynamIx HR squared unit (figure 1) with 25-to-100-micron scanner, ST-6 image plates or the ultra-high res UR1’s to capture the image. Lavender have a set of laptops fully loaded with DynamIx viewing software (figure 4) to view loss of wall corrosion, measure defects, and assess grayscale and contrast requirements. The Fujifilm system is simple to use and produces a fantastic image for evaluation against given standards.

If you would like to book your CRT course, contact us.

Or view our course schedule.